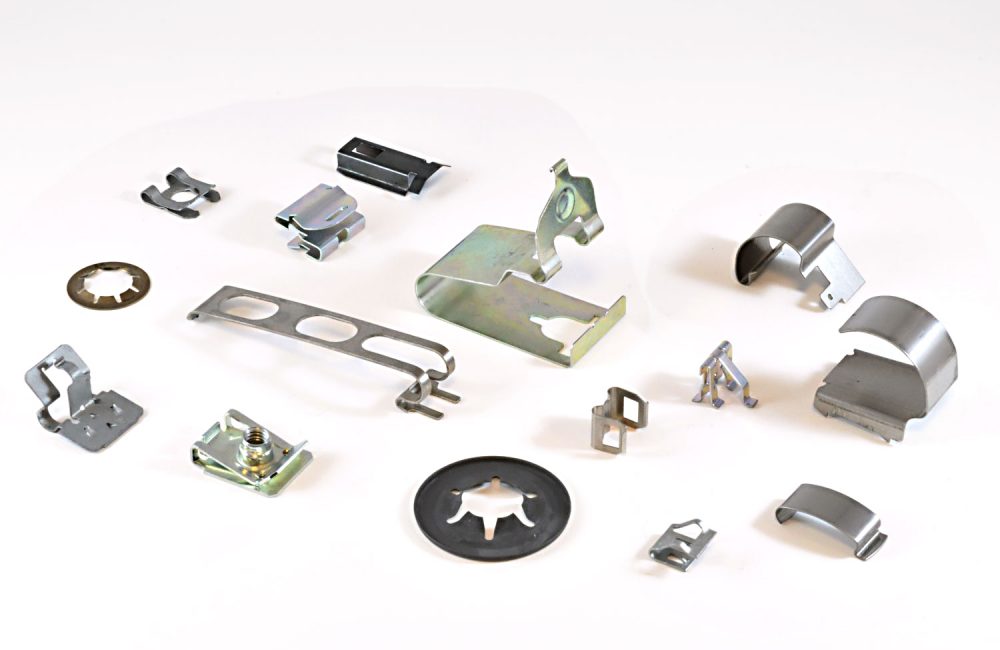

Technologies Tape

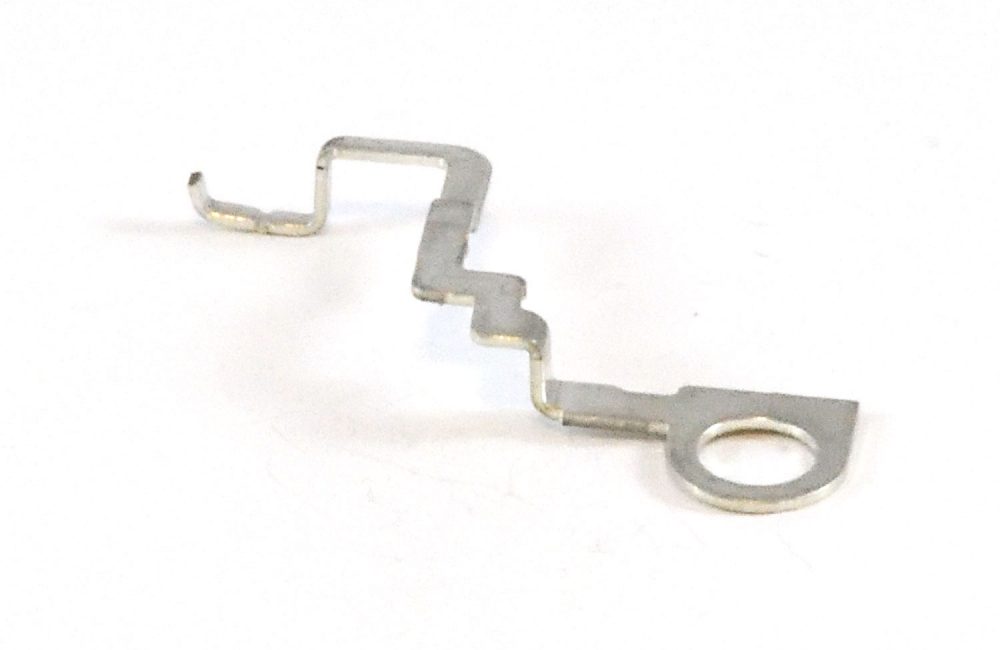

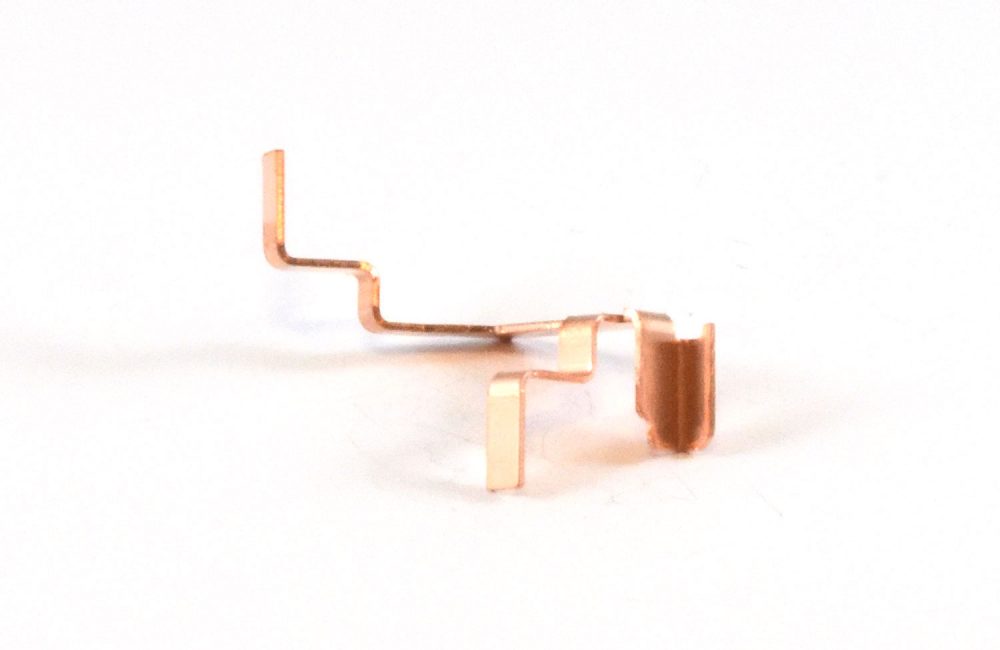

Technologies Tape - Springs

Materials: carbon steel in compliance with UNI EN 10132, processed as both annealed and pre-hardened, stainless steel in compliance with UNI EN 10151, phosphorous bronze in compliance with UNI EN 1652, copper alloys such as CuNiSi or CuFe2P, or any other material available on the market.

Dimensions of the tape: thickness from 0.15 mm to 6 mm, width from 1 mm to 550 mm.

Treatments: all the ones that are available on the market, on both the tape and on the shaped part.

Spot checks: geometric by gauges and CNC optic measurement machines, loads on mechanized automatic dynamometers, fatigue tests, thicknesses of the surface layers on X-ray machinery.

Automatic checks: geometric with 100% selecting machinery equipped with three video-cameras.

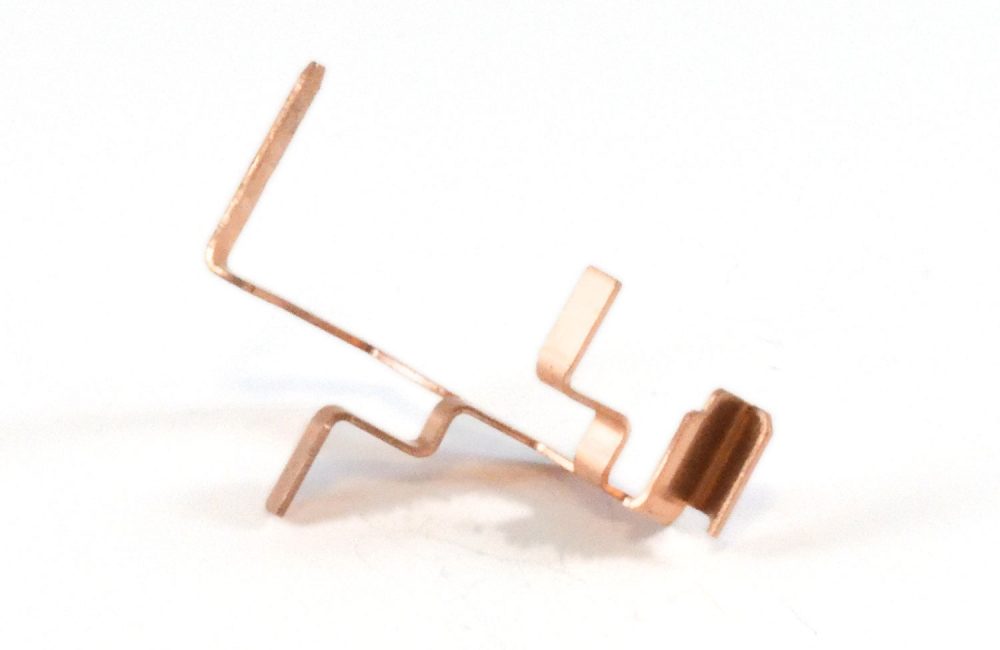

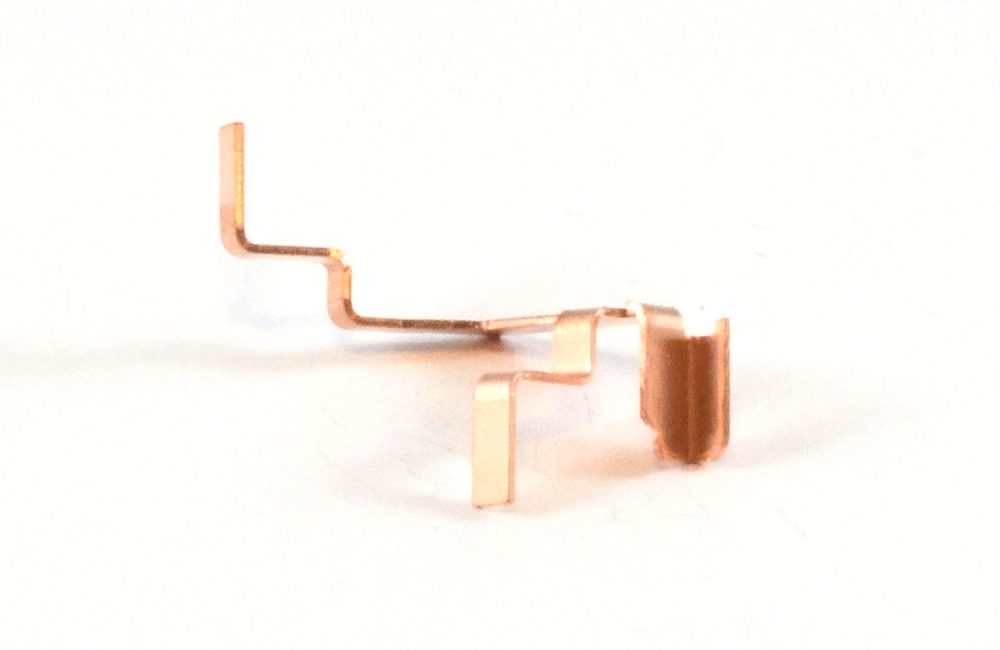

Technologies Tape - Contacts

Materials: copper and copper alloys (brass and phosphorous bronze) in compliance with UNI EN 1652, copper alloys such as copper-beryllium, CuNiSi or CuFe2P, steel in compliance with UNI EN 10139 and UNI EN 10130, carbon steel in compliance with UNI EN 10132 processed both as annealed and pre-hardened, stainless steel in compliance with UNI EN 10151, or any other material available on the market.

Dimensions of the tape: thickness from 0.15 mm to 6 mm, width from 1 mm to 550 mm.

Treatments: all the ones available on the market, performed on the tape, on the shaped part and on the pre-sheared strip. In this last case, the treatment can be performed also selectively (e.g.: nickel base on the whole part and gold plating on some areas only).

Spot checks: geometric by gauges and CNC optic measurement machines, loads on mechanized automatic dynamometers, fatigue tests, thicknesses of the surface layers on X-ray machinery.

Automatic checks: geometric with 100% selecting machinery equipped with three video-cameras

Technologies Tape - Washers

Materials: carbon steel in compliance with UNI EN 10132, processed as both annealed and pre-hardened, steel in compliance with UNI EN 10139 and UNI EN 10130, stainless steel in compliance with UNI EN 10151, copper and copper alloys (brass and phosphorous bronze) in compliance with UNI EN 1652, copper alloys such as CuNiSi or CuFe2P, or any other material available on the market.

Dimensions of the tape: thickness from 0.15 mm to 6 mm, width from 1 mm to 550 mm.

Treatments: all the ones that are available on the market, on both the tape and on the shaped part.

Spot checks: geometric by gauges and CNC optic measurement machines, loads on mechanized automatic dynamometers, fatigue tests, thicknesses of the surface layers on X-ray machinery.

Automatic checks: geometric with 100% selecting machinery equipped with three video-cameras

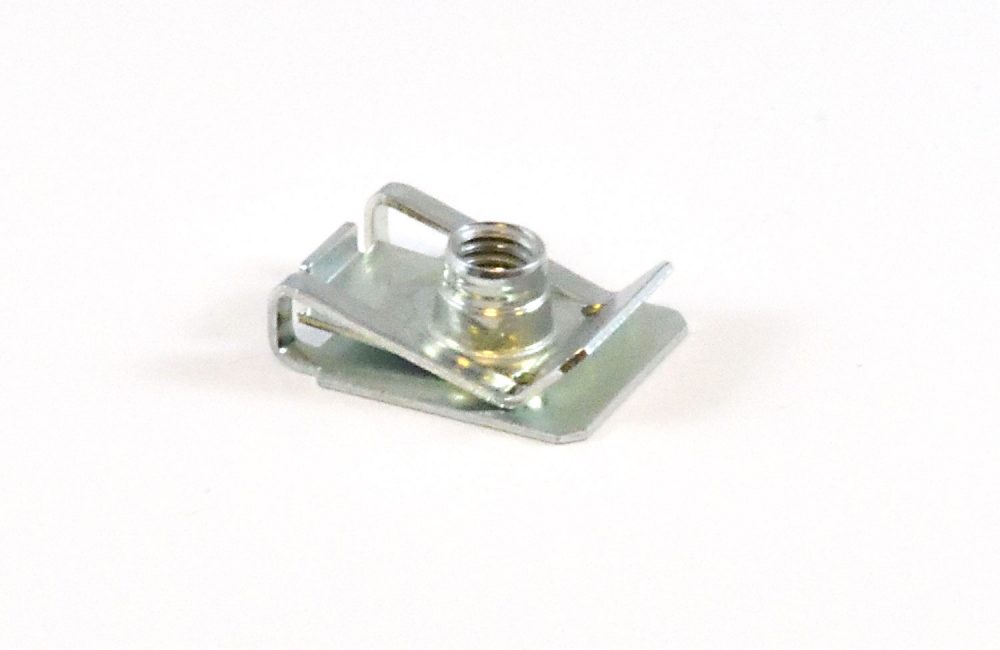

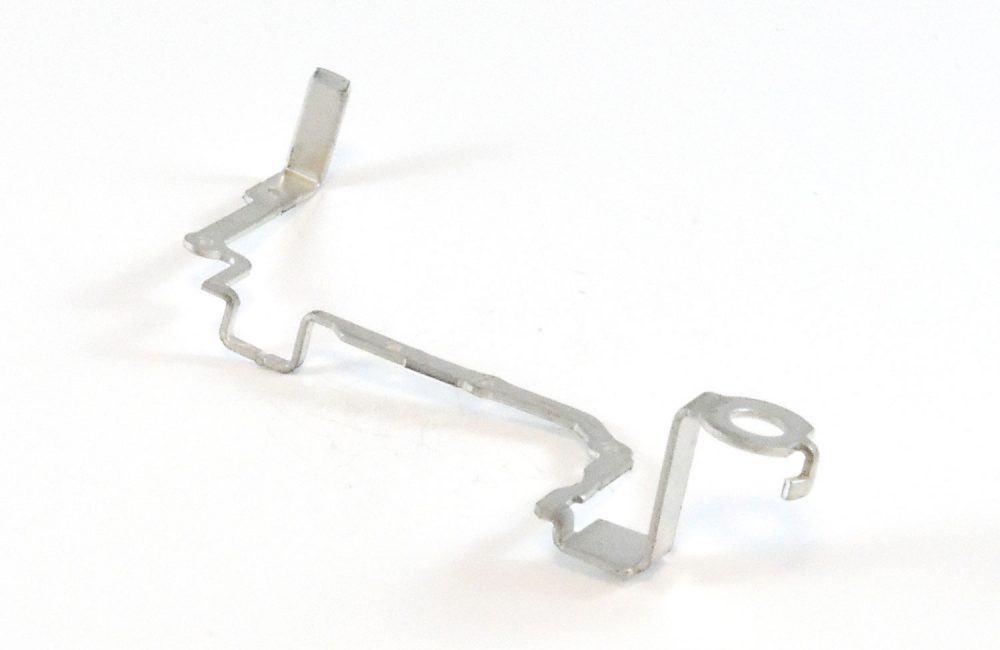

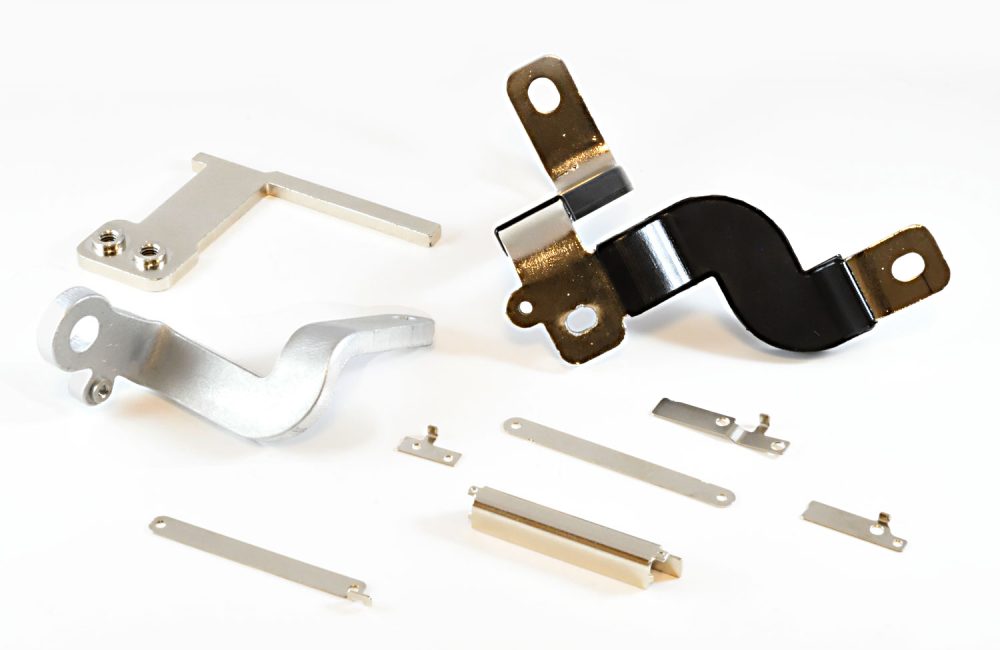

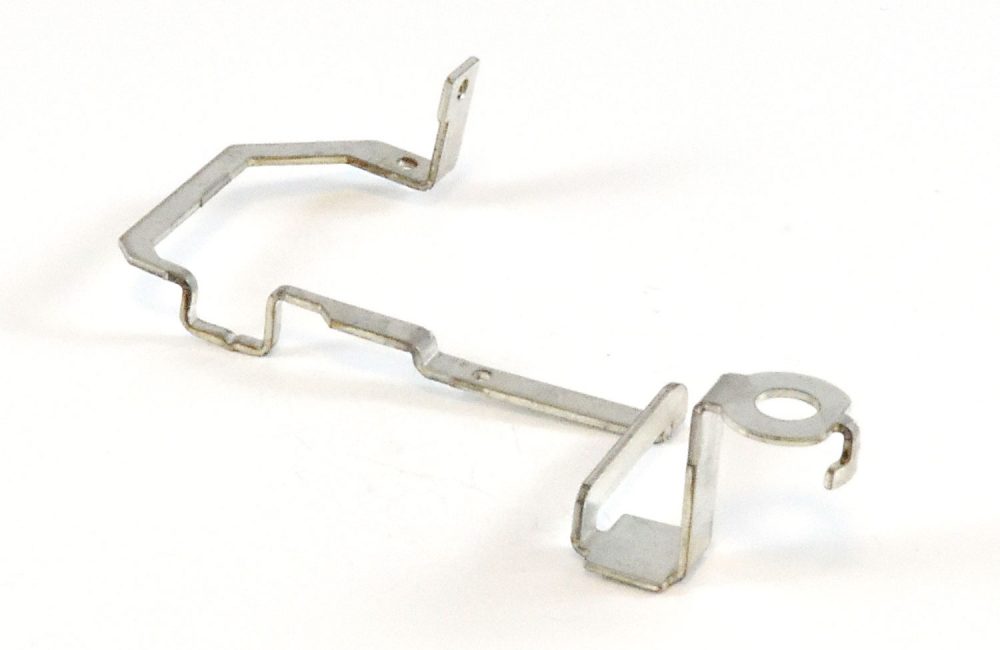

Technologies Tape - Attachment Systems

Materials: carbon steel in compliance with UNI EN 10132, processed as both annealed and pre-hardened, steel in compliance with UNI EN 10139 and UNI EN 10130, stainless steel in compliance with UNI EN 10151, copper and copper alloys (brass and phosphorous bronze) in compliance with UNI EN 1652, copper alloys such as CuNiSi or CuFe2P, or any other material available on the market.

Dimensions of the tape: thickness from 0.15 mm to 6 mm, width from 1 mm to 550 mm.

Treatments: all the ones that are available on the market, on both the tape and on the shaped part.

Spot checks: geometric by gauges and CNC optic measurement machines, loads on mechanized automatic dynamometers, fatigue tests, thicknesses of the surface layers on X-ray machinery.

Automatic checks: geometric with 100% selecting machinery equipped with three video-camera.

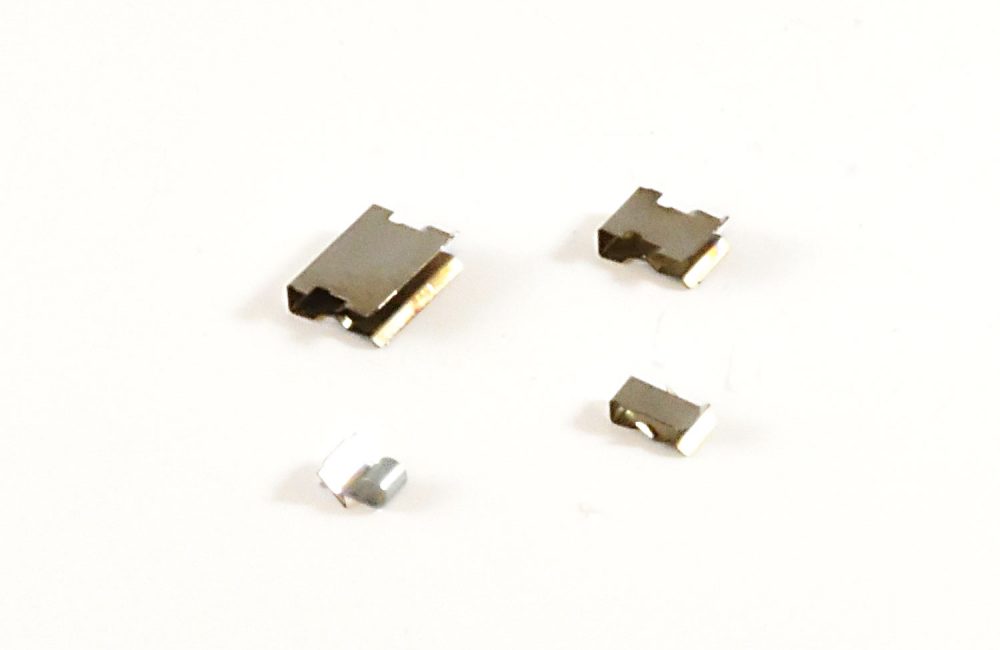

Technologies Tape - Balancing Clips

Materials: carbon steel in compliance with UNI EN 10132, processed as both annealed and pre-hardened, stainless steel in compliance with UNI EN 10151 or any other material available on the market.

Dimensions of the tape: thickness from 0.15 mm to 1.5 mm, width from 1 mm to 50 mm.

Treatments: all the ones that are available on the market, on both the tape and on the shaped part.

Spot checks: geometric by gauges and CNC optic measurement machines, loads on mechanized automatic dynamometers, fatigue tests, thicknesses of the surface layers on X-ray machinery, tightness on fans on test bench.

Automatic checks: geometric with 100% selecting machinery equipped with three video-cameras.

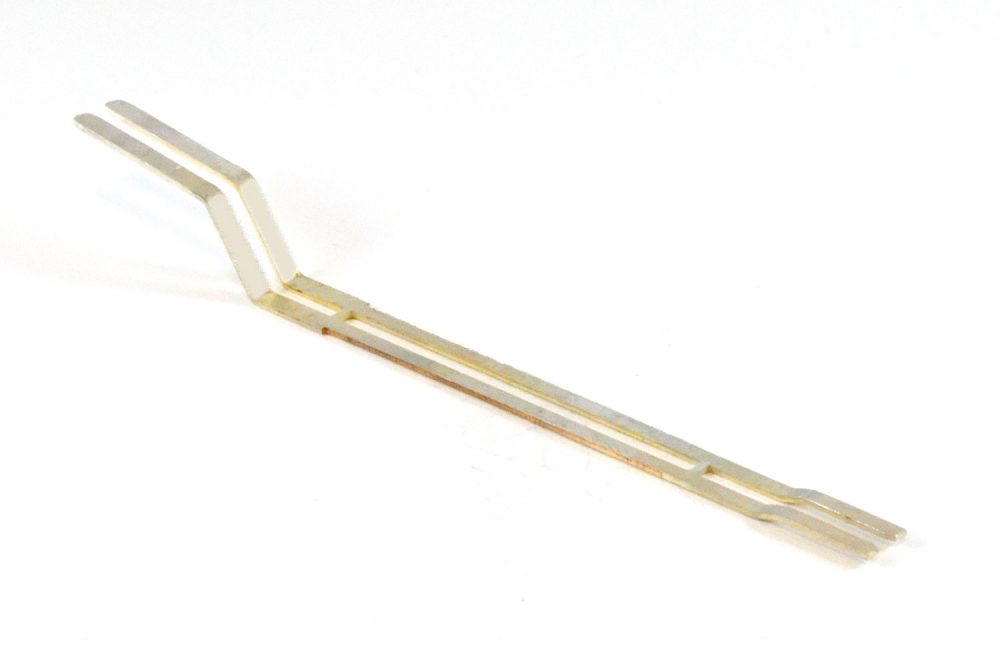

Technologies Tape - Busbar

Materials: copper and copper alloys such as brass and phosphorous bronze in compliance with UNI EN 1652 or copper-beryllium, CuNiSi, CuFe2P, aluminum in the different alloys or any other material available on the market.

Dimensions of the tape: thickness from 0.15 mm to 6 mm, width from 1 mm to 550 mm.

Treatments: all the ones available on the market, performed on the tape, on the shaped part and on the pre-sheared strip. In this last case, the treatment can be performed also selectively (e.g.: nickel base on the whole part and tinning on some areas only).

Spot checks: geometric by gauges and CNC optic measurement machines, loads on mechanized automatic dynamometers, fatigue tests, thicknesses of the surface layers on X-ray machinery.

Automatic checks: geometric with 100% selecting machinery equipped with three video-cameras.

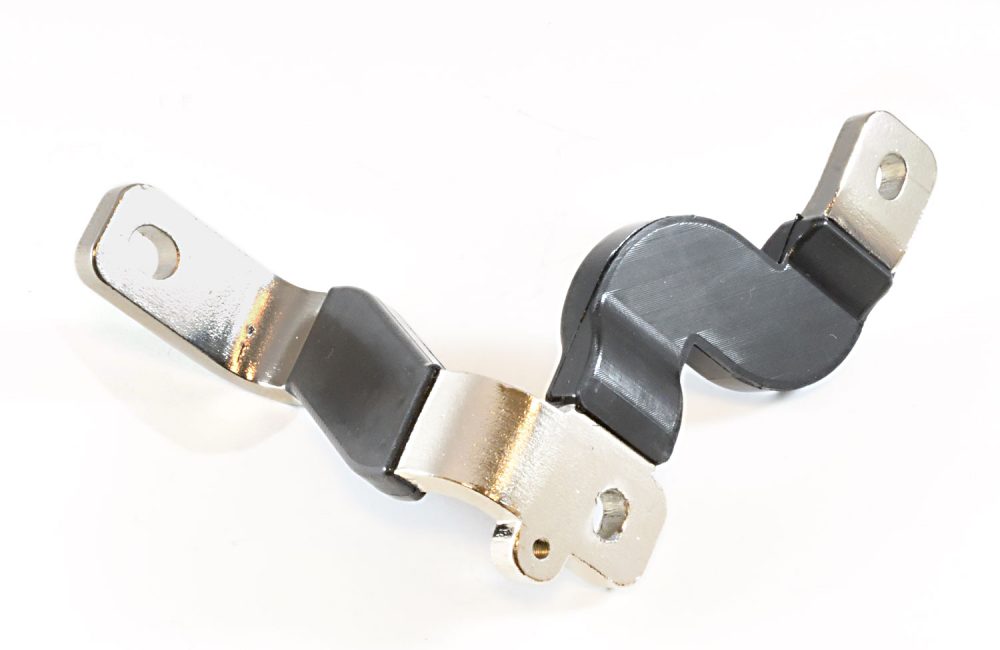

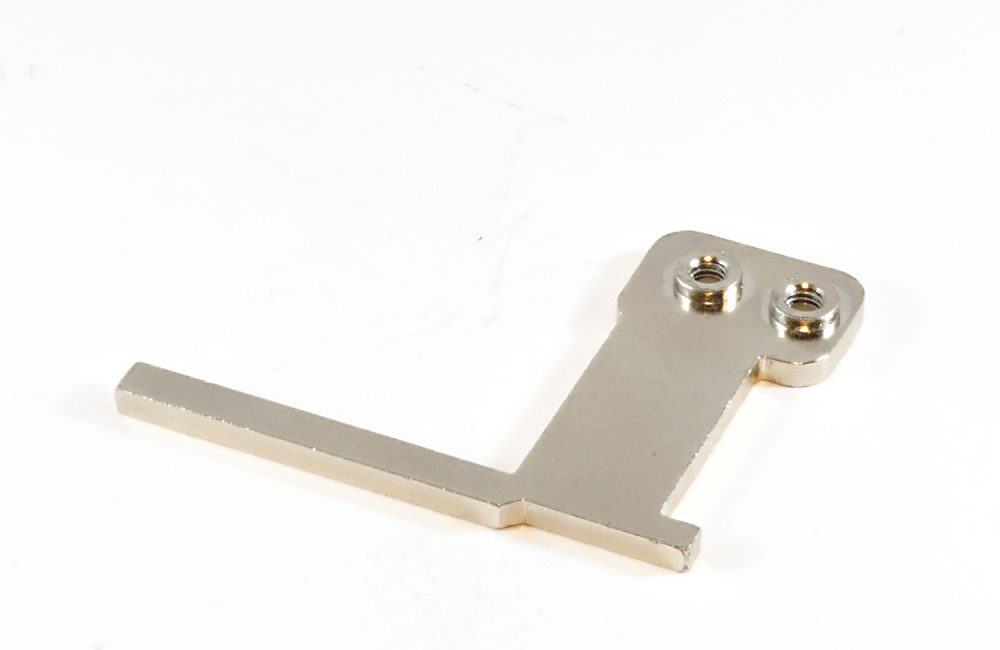

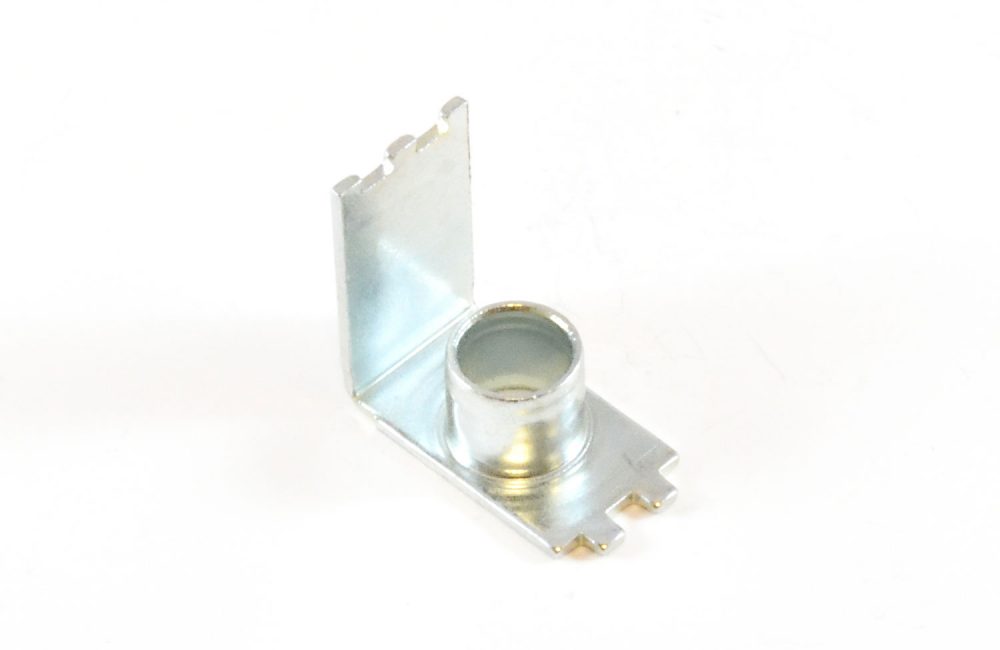

Technologies Tape - Bushings

Bevel and oval, closed with or without deep drawn flange, open with or without flanged, open clipped, with side piercing for insert-molding.

Obtained from sheared, edged tape or strap.

Materials: steel in compliance with UNI EN 10139 and UNI EN 10130, carbon steel in compliance with UNI EN 10132, stainless steel or any other material available on the market.

Dimensions of the tape: thickness from 0.5 mm to 3 mm, width from 1 mm to 100 mm.

Treatments: all the ones that are available on the market, on both the tape and on the shaped part.

Spot checks: geometric by gauges and CNC optic measurement machines, loads on mechanized automatic dynamometers, fatigue tests, thicknesses of the surface layers on X-ray machinery.

Automatic checks: geometric with 100% selecting machinery equipped with three video-cameras.

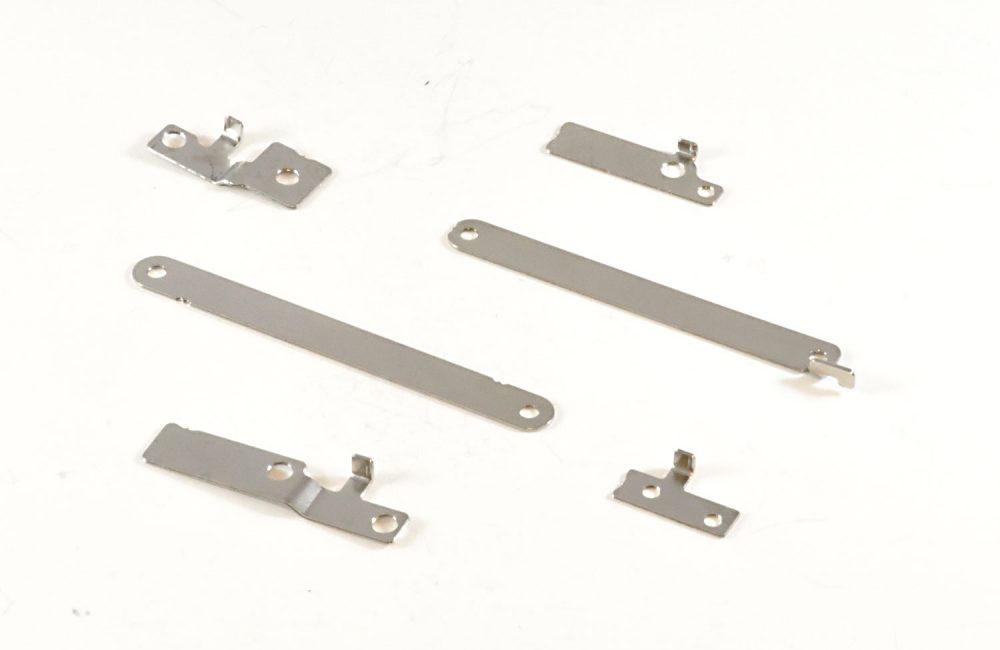

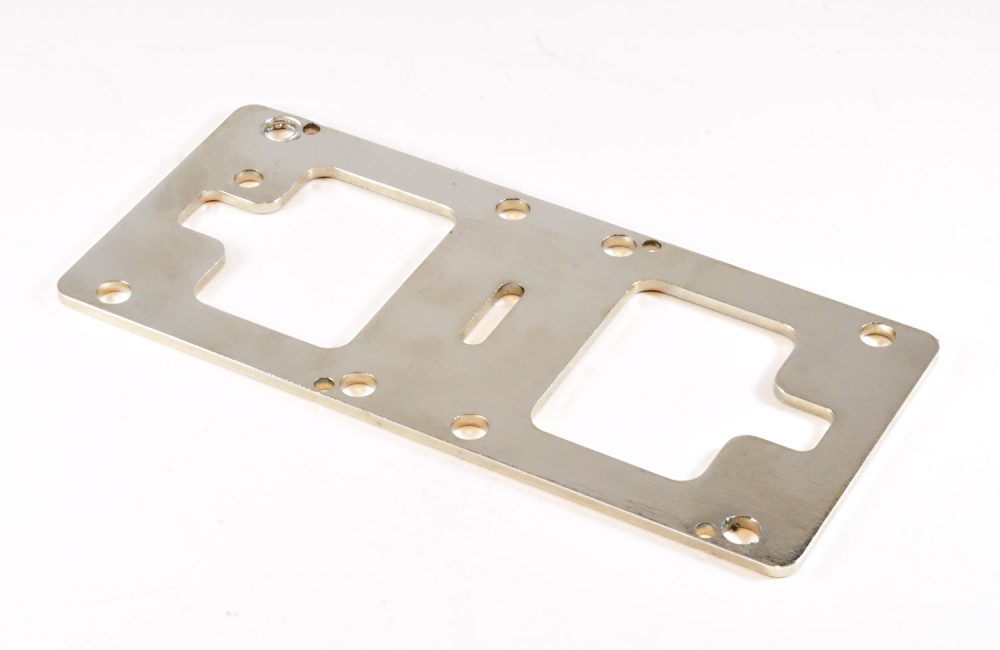

Technologies Tape - Sheared parts

Materials: carbon steel in compliance with UNI EN 10132, processed as both annealed and pre-hardened, steel in compliance with UNI EN 10139 and UNI EN 10130, stainless steel in compliance with UNI EN 10151, copper and copper alloys (brass and phosphorous bronze) in compliance with UNI EN 1652 or any other material available on the market.

Dimensions of the tape: thickness from 0.15 mm to 6 mm, width from 1 mm to 550 mm.

Treatments: all the ones available on the market, performed on the tape, on the shaped part and on the pre-sheared strip. In this last case, the treatment can be performed also selectively (e.g.: nickel base on the whole part and gold plating on some areas only).

Spot checks: geometric by gauges and CNC optic measurement machines, loads on mechanized automatic dynamometers, fatigue tests, thicknesses of the surface layers on X-ray machinery.

Automatic checks: geometric with 100% selecting machinery equipped with three video-cameras.