Processes

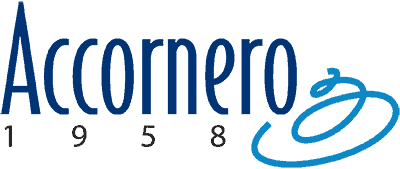

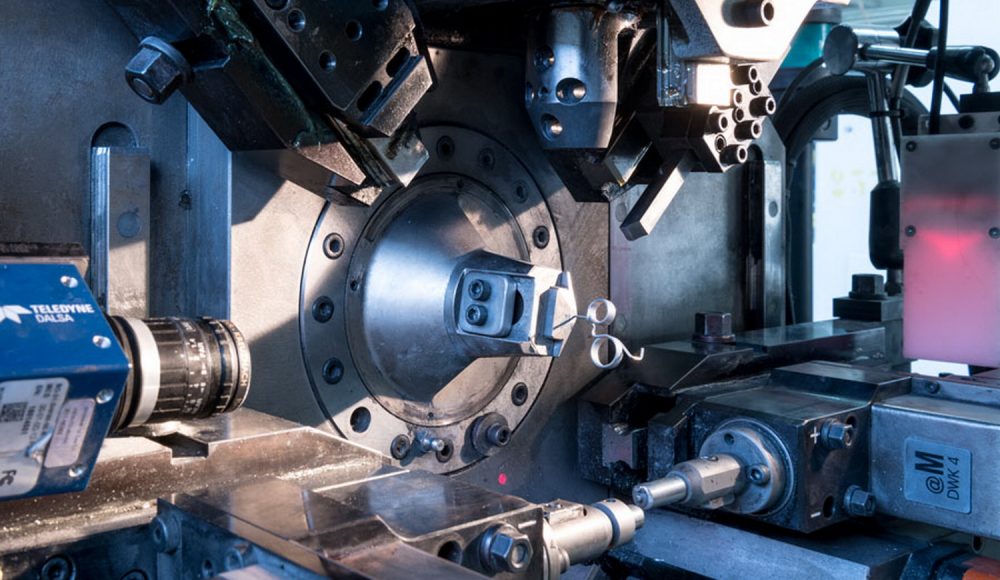

Processes - Wire

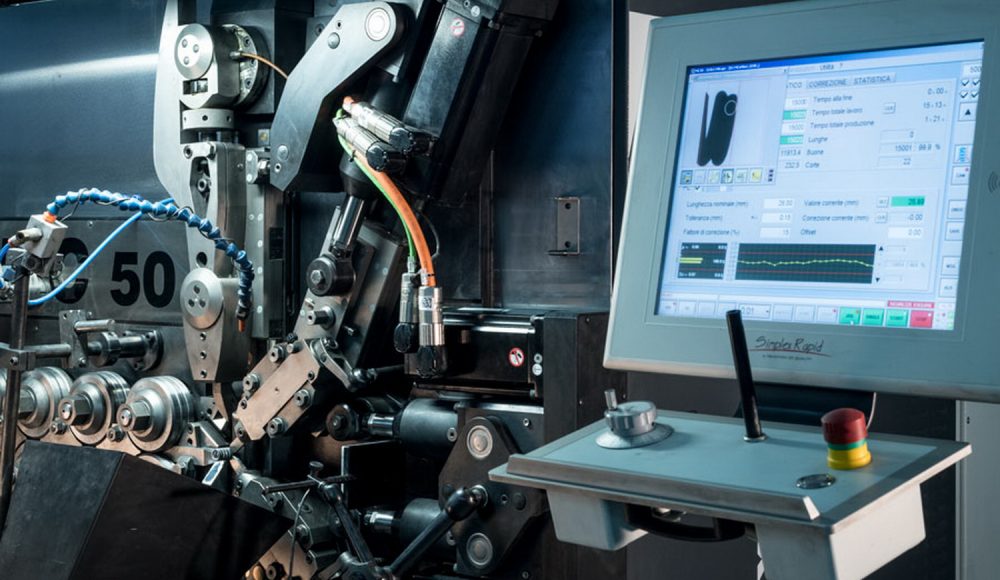

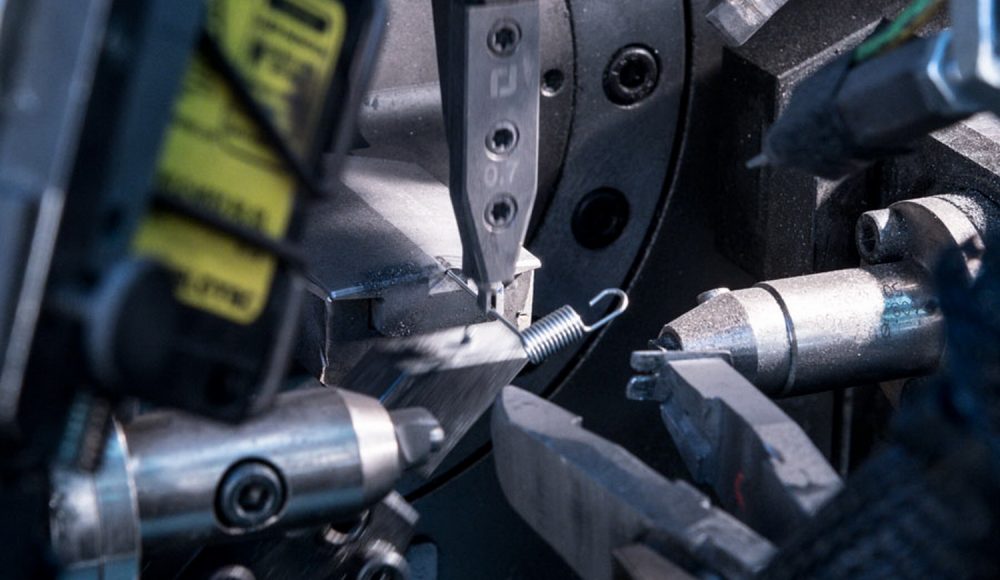

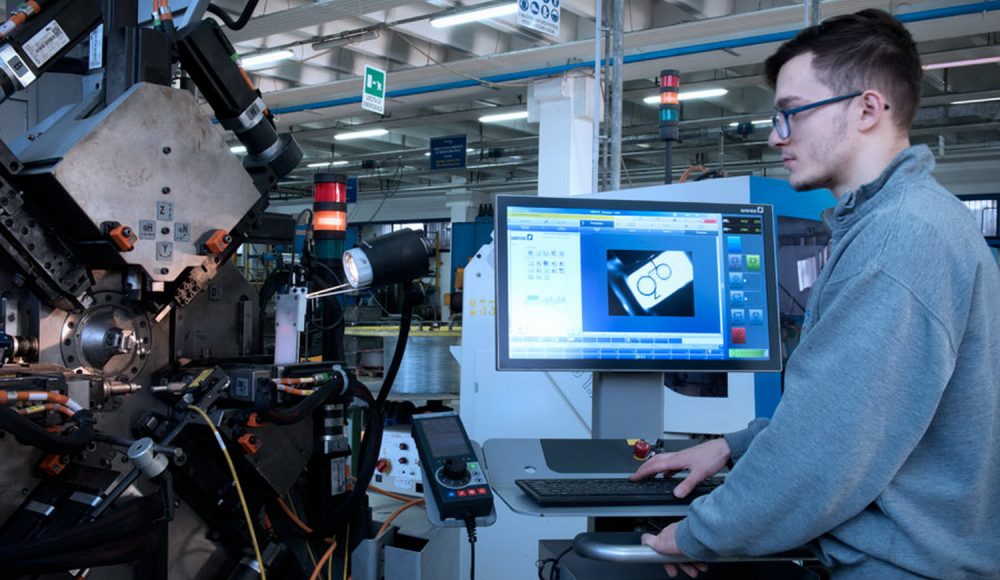

For the processing of the metal wire, we use: Simplex Rapid coil winders for the compression springs; Wafios twisting machines for the torsion and traction springs as well as for the shaped wires; Mec eyletting machines for the traction springs; Bihler stamping-bending machines for the shaped wires.

We address the leading manufactures in the different fields in order to focus on the product, giving for granted the reliability of the technology.

Machinery that can operate with different qualities of materials and diameters from 0.15 mm to 6 mm. During the process, automatic and spot checks are performed on the main functional characteristics.

We perform any type of surface treatment. We can verify the fatigue life of the products we develop. We set up small lines downstream the shaping machine in order to

reduce the handling and – subsequently – contain the costs.

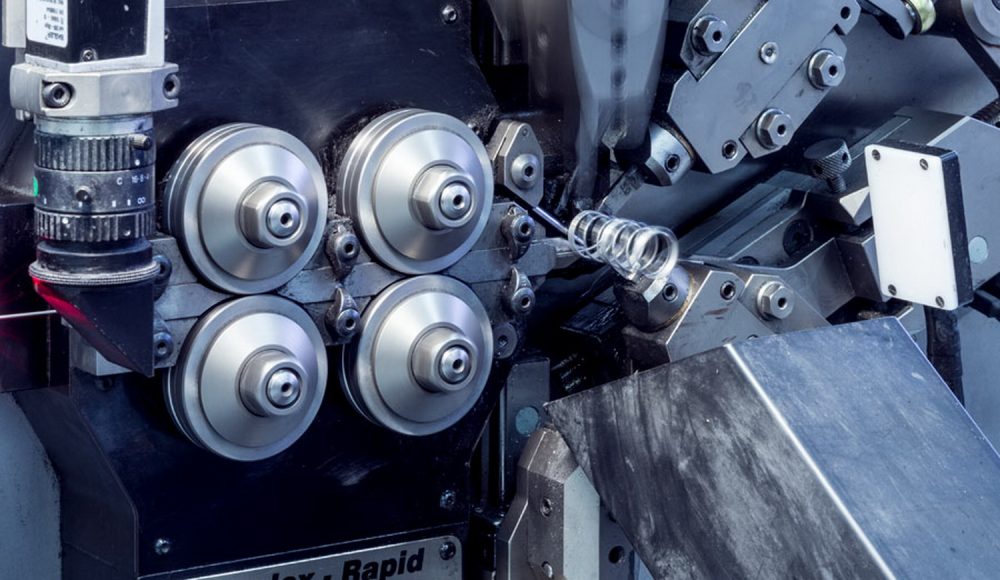

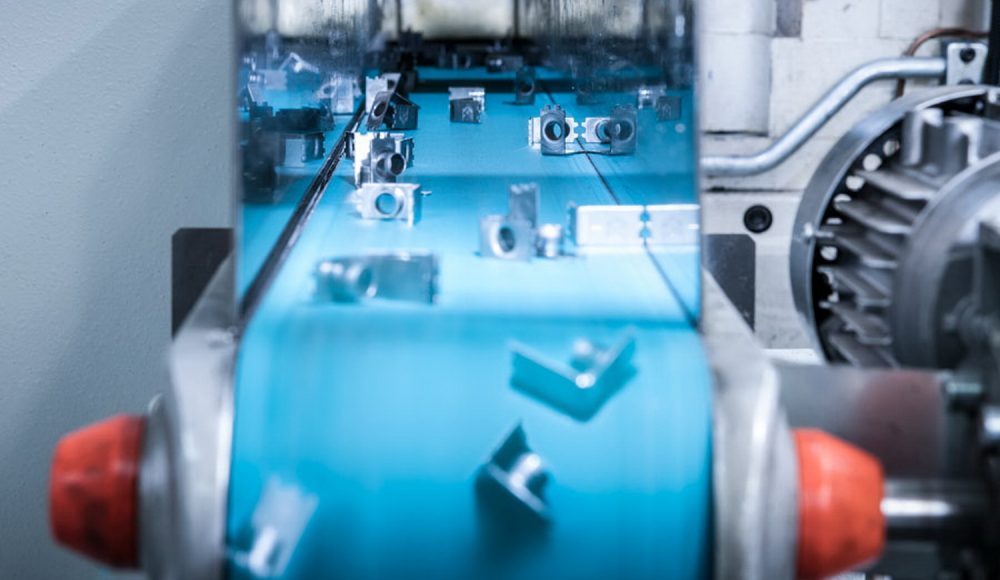

Processes - Tape

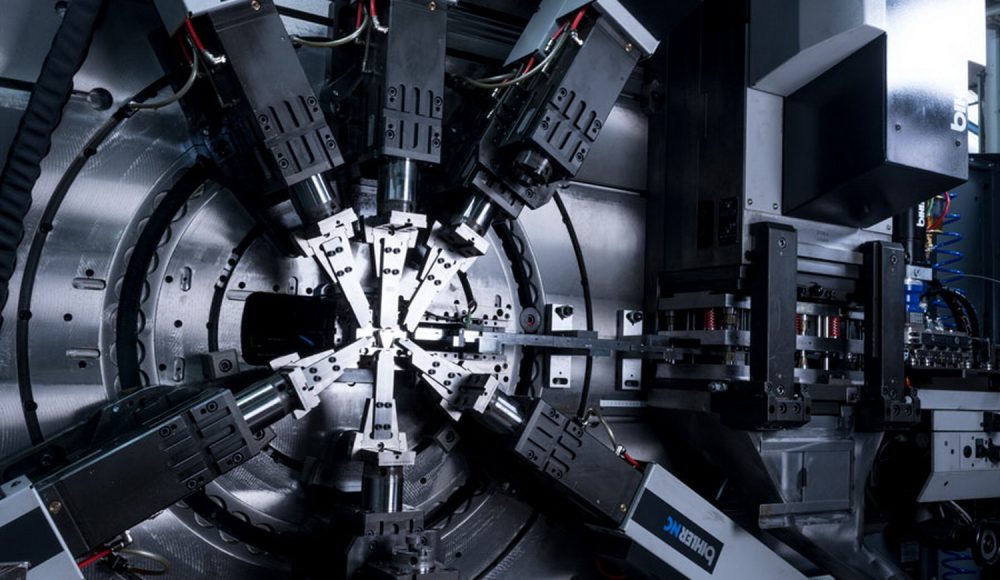

We can shear, bend, thread, deep-draw, clip and turn the tape into circlips, contacts, brackets, plates, bushing, elastic washers and fasteners .

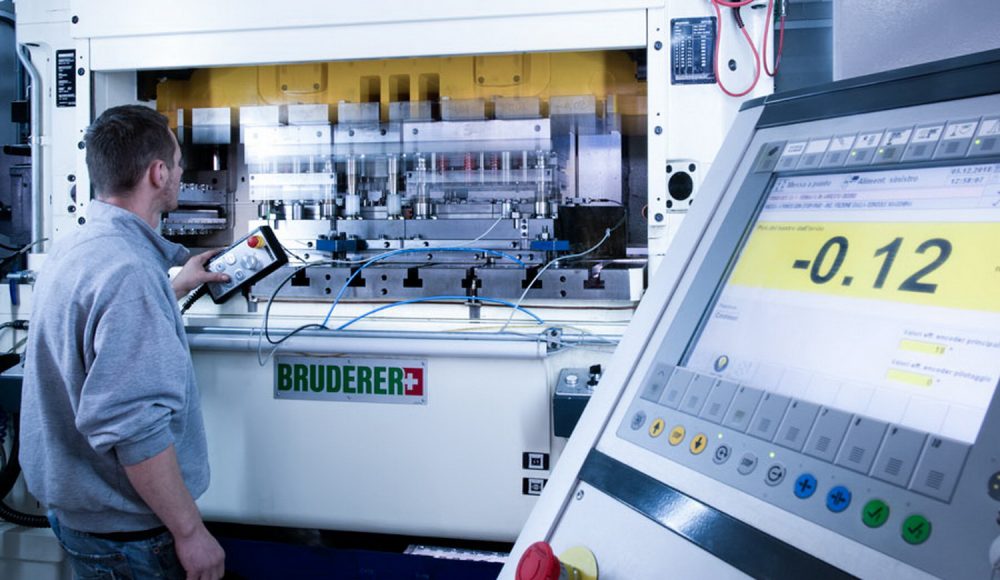

We process tapes in different materials with thicknesses from 0.1 mm to 6 mm on mechanical and CNC stamping-bending machines (Bihler) and presses (Bruderer and Minster).

We address the leading manufactures in the different fields in order to focus on the product, giving for granted the reliability of the

machinery.

We can carry out any type of heat and surface treatment, including the either selective or non-selective continuous surface treatments on pre-sheared tape.

We develop small lines downstream the shaping machinery in order to reduce the handling and – therefore – contain the costs.

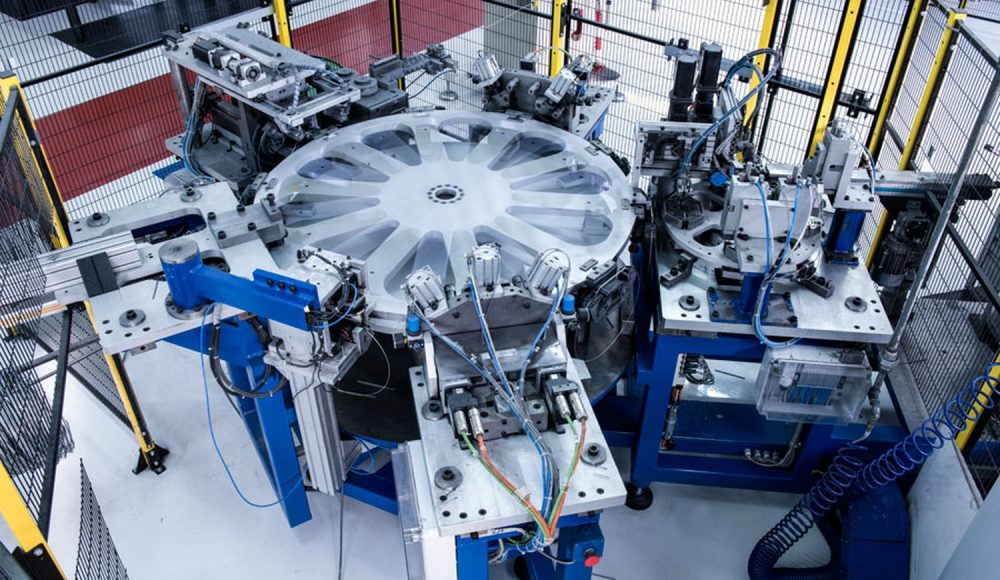

Processes - Assembled Parts

After developing the parts in either wire or tape, we assemble them in the aim of providing the client not with a mere spring or sheared part, but with a finished component, ready to be utilized.

When the quantities make it suitable, we develop automatic assembly machinery in order to ensure the quantities and the quality consistency required by our customers.

Processes - Plastic and Molden Parts

The evolution of the products and the will to supply complex components has led us to purchase the know-how in thermoplastic molding.

Besides the individual parts, we develop products that mate several thermoplastic materials and metal parts.

For the thermoplastic molding, we use electrical Sumitomo-Demag machines.